Smart Manufacturing – Opportunities for Industrial & Systems Engineers

By Thorsten Wuest, assistant professor and J. Wayne & Kathy Richards Faculty Fellow, Industrial and Management

Systems Engineering at West Virginia University

Introduction and Overview

It is almost impossible today as an industrial engineer to avoid conversations and discussions hovering around Smart Manufacturing and Industry 4.0. Whether one is active in an industrial or academic context, Smart Manufacturing seems to be omnipresent at every meeting, conference, or trade show. However, while everyone has a certain

understanding and opinion about the topic, there is still some confusion around what it truly means and how it relates to the job of an industrial and systems engineer. The objective of this short article is to provide a concise overview of Smart

Manufacturing, its opportunities and challenges, and ultimately argue why IEs are uniquely qualified to spearhead the charge to master the fourth industrial revolution.

First, we will put Smart Manufacturing and Industry 4.0 in a historic context. Both build on the Intelligent Manufacturing notion that predates both terms, Industry 4.0 and Smart Manufacturing. The term fourth industrial revolution (a.k.a. Industry 4.0 or I4) was coined not too long ago, in 2011 by a German government initiative to

prepare the German manufacturing industry for the digital future [1]. While the name is certainly controversial – since when are revolutions proclaimed before they actually happen? – it rapidly caught traction and is now an established terminology across the globe. It builds on the notion that after the first three major industrial

revolutions, mechanization of labor, division of labor, and computerization of the shop-floor, the convergence of the physical and virtual world, in form of so-called Cyber-physical Systems (CPS) is understood to be the next major interruption of the manufacturing industry and beyond (see Fig. 1). The question remains, was

manufacturing not smart, or even "dumb" before? No, not at all! The smartness was however associated more with the human operators and process planners – the human experts – and not inherited in the system itself. We all know the experienced operators of complex machine tools who seem to know when a machine is

about to fail. The goal in a Smart Manufacturing System is to reproduce this "gut feeling" by collecting data and analyzing it to draw conclusions.

Smart Manufacturing originates in the US and is defined as "a data intensive application of information technology at the shop-floor level and above to enable intelligent, efficient and responsive operations" [3]. While there are several other, more comprehensive definitions available they all emphasize the use of Information and Communication

Technology (ICT), data, and advanced data analytics to improve manufacturing operations at all levels of the supply network. An important aspect that differentiates Smart Manufacturing from many other initiatives, is the specific emphasis on human ingenuity within

the framework. Humans are not to be simply replaced by artificial intelligence and cognitive automation on the shop-floor but their capabilities are to be enhanced by smart customized solutions for the specific area. The importance of product and process information and data, enabling technologies, and

(human or machine inherent) knowledge is commonly accepted [2, 4, 5].

Smart Manufacturing is often used in conjuncture with Advanced Manufacturing. At times the two terms are used as synonyms. However, I believe this is not the intention and we need to be clear about the meaning of each term to not increase the complexity by adding additional confusion. In our view, Smart and Advanced Manufacturing describe

distinct areas of the new manufacturing realities – and can be seen as two sides of the same (industry 4.0) medallion (see Fig. 2). Smart Manufacturing at its core focuses on connectivity, virtualization, and data utilization, while Advanced Manufacturing focuses on manufacturing process technologies

such as automation, robotics, and additive manufacturing. Nevertheless, there is no sharp dividing line between the two concepts and in order to be successful in the future, companies need to embrace both.

Smart Manufacturing is often used in conjuncture with Advanced Manufacturing. At times the two terms are used as synonyms. However, I believe this is not the intention and we need to be clear about the meaning of each term to not increase the complexity by adding additional confusion. In our view, Smart and Advanced Manufacturing describe

distinct areas of the new manufacturing realities – and can be seen as two sides of the same (industry 4.0) medallion (see Fig. 2). Smart Manufacturing at its core focuses on connectivity, virtualization, and data utilization, while Advanced Manufacturing focuses on manufacturing process technologies

such as automation, robotics, and additive manufacturing. Nevertheless, there is no sharp dividing line between the two concepts and in order to be successful in the future, companies need to embrace both.

Figure 1: Four Industrial

Revolutions [2]

Figure 1: Four Industrial

Revolutions [2]

Smart Manufacturing originates in the US and is defined as “a data intensive application of information technology at the shop-floor level and above to enable intelligent, efficient and responsive operations” [3]. While there are several other, more comprehensive definitions

available they all emphasize the use of Information and Communication Technology (ICT), data, and advanced data analytics to improve manufacturing operations at all levels of the supply network. An important aspect that differentiates Smart Manufacturing from many other initiatives, is the specific

emphasis on human ingenuity within the framework. Humans are not to be simply replaced by artificial intelligence and cognitive automation on the shop-floor but their capabilities are to be enhanced by smart customized solutions for the specific area. The importance of product and process information and data,

enabling technologies, and (human or machine inherent) knowledge is commonly accepted [2, 4, 5].

Smart Manufacturing is often used in conjuncture with Advanced Manufacturing. At times the two terms are used as synonyms. However, I believe this is not the intention and we need to be clear about the meaning of each term to not increase the complexity by adding additional confusion. In our view, Smart and

Advanced Manufacturing describe distinct areas of the new manufacturing realities – and can be seen as two sides of the same (industry 4.0) medallion (see Fig. 2). Smart Manufacturing at its core focusses on connectivity, virtualization, and data utilization, while Advanced Manufacturing focusses on

manufacturing process technologies such as automation, robotics, and additive manufacturing. Nevertheless, there is no sharp dividing line between the two concepts and in order to be successful in the future, companies need to embrace both.

Figure 2: Two sides of the same medallion - Advanced & Smart

Manufacturing

Figure 2: Two sides of the same medallion - Advanced & Smart

Manufacturing

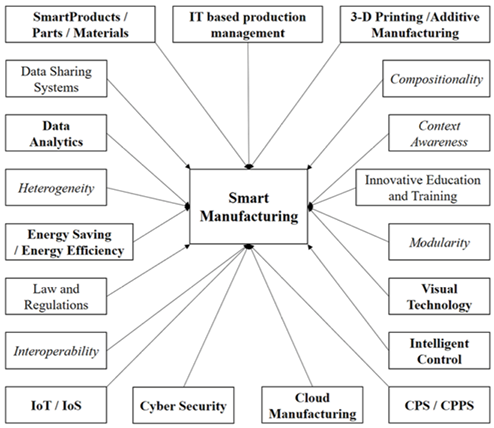

Smart Manufacturing Technologies, Characteristics, and enabling Factors

An important aspect of Smart Manufacturing for both research and industrial application is revolving around associated technologies. For instance, for companies it is important to understand what technologies are relevant and might be worthwhile to assess or

invest in. While for researchers, identifying areas where additional research is required to develop technologies further to address current needs will help to make an impact and prepare students for their future careers. Therefore, we will briefly introduce technologies, characteristics, and enabling factors that

are associate with Smart Manufacturing. This is mainly a summary of our recent journal publication regarding this topic [6] - in case you are interested in a more in-depth analysis please refer to the original publication which is available

open access. In a comprehensive study, we identified 38 different technologies, 27 characteristics and 7 enabling factors that were associated with Smart Manufacturing. The technologies ranged from machine learning to augmented reality, the characteristics from agility

to decentralized control, and enabling factors from STEP standards to MTConnect [9]. In a following step, we clustered the list based on their semantic similarity. The result of this clustering is illustrated in Fig. 3.

Figure 3: Visual representation of all identified Smart Manufacturing

technologies (bold),

characteristics and enabling factors [6]

It has to be noted, that Additive Manufacturing is included in this list despite the association with Advanced Manufacturing based on the methodology used. It showcases, that some authors use Smart and Advanced Manufacturing interchangeable.

Research Opportunities for Industrial & Systems Engineers

In this section, we will discuss a selection of pressing research issues that require our attention in order to successfully support the manufacturing industry in its digital transformation. This is not intended to be a comprehensive list, as there are several more

issues that deserve our attention. However, we believe the following challenges pose interesting and worthwhile problems to tackle for industrial and systems engineers. Given the width of the field, we group the research issues in three categories: Technical research issues, methodological research issues, and

business case research issues [2]. This again reflects the interdisciplinary nature and complexity of the field.

Technical research issues:

- Standards / interfaces: In order to harvest the promise of Smart Manufacturing on the shop-floor and beyond, a strong foundation that allows us to connect and communicate is key – standards and interfaces are crucial to achieve this vision.

- Sensors / actuators: With the dawn of the Internet of Things (IoT) sensors and actuators are everywhere, more powerful, and cheaper than ever. However, in an industrial setting, the requirements for sensors and actuators are more rigorous than in our homes. Therefore, we need to continue

to develop this field to provide the nodes for our growing network of manufacturing things.

- Data quality: Data is the lifeblood of all Smart Manufacturing initiatives. We need to develop new ways to assess and ideally guarantee a high quality of our data as an input for our advanced algorithms.

- Data handling: Developing new and expanding existing database systems and platforms capable of storing, retrieving, and manipulate vast amount of data on premises, in the cloud, in between (fog/edge), as well as combinations (hybrid systems) are required to facilitate collaboration and

truly enable cross-domain learning.

- Data analytics / machine learning: Deriving a decision from a vast amount of data (Big Data) requires continuous efforts in developing new and adapting current algorithms to optimize predictions, computing efficiency, and ease of use just to name a few.

- Data security / cyber security: Manufacturing facilities are among the most attacked entities according to the US government. With increasing connectivity, the threat and potential damage of cyber-attacks increases exponentially. Therefore, we need to invest our efforts in developing new

safeguards for our industrial Smart Manufacturing Systems that improve security while minimizing the effect on (intended) data exchange and flow.

Methodological research issues:

- Reference models: Smart Manufacturing Systems are inheritably complex. This represents a significant entry barrier for manufacturing companies. Reference models providing a structure and guideline to manage this complexity are needed as well as new adaptations/extensions of

existing ones for specific industries and e.g., SMEs.

- Visualization: Deriving insights from large amounts of data is only one side of the medallion. Communicating the insights in an appropriate, efficient, and effective manner is equally important to create value and impact. For example, the C-level executive requires a very different

visualization of the same data than the operator of a certain machine tool or the maintenance team. Visualization is strongly related to certain technologies such as digital twins, virtual and augmented reality.

- Services / applications marketplaces: Given the complexity of a Smart Manufacturing System, one common approach is to address the different functionalities through composable (micro-)services. Orchestrating those and creating efficient marketplaces to bring the various stakeholders together is a

challenge that is yet to be fully addressed.

- Requirements engineering: Requirements engineering remains a continuous issue for all engineering projects. With the dawn of Smart Manufacturing and Industry 4.0, the possibility to collect (IoT) and analyze large amounts of usage data (Big Data) opens up new opportunities to derive

insights in the real users’ needs and requirements directly from the way they interact with the products/systems. New methods and ways to automate the translation the data and insights into design requirements need to be developed.

- Operator 4.0: While certain tasks in the manufacturing environment will increasingly be automated, both physical and cognitive in nature, we believe that the human operator will remain a key part of a Smart Manufacturing System. New ways to provide additional capabilities to

the human operator is referred to as the tech-augmented ‘Operator 4.0’ [7]. Case studies and innovative solutions to extend the Operator 4.0 are in high demand.

Business case research issues:

- Privacy issues: Smart Manufacturing revolves around data collection, sharing, and analysis. This introduces new challenges in the data privacy are, which we believe is different from the data security aspect itself. The ethics behind sharing and analyzing for example user data need to

be critically assessed as well as new rules and standards are needed.

- Investment issues: Similar to most new developments that require new technologies, redesign of processes, and training, entering the Smart Manufacturing journey will require a significant investment. Especially for SMEs, this initial investment might pose a barrier as they are more likely

to have limited resources (monetary but also expertise-wise) [8]. Identifying ways to reduce this initial investment through, e.g., new open source and modular solutions will impact the adoption in those cases. Collecting lessons learned and best practices from recent implementations as well as case studies

will further lower the bar to engage in modernizing manufacturing operations.

- Servitization / servitized business

models: A side effect of introducing connectivity and (real-time) access to machine tool data is the possibility to introduce new business models based on pay-per-use or pay-per-outcome principles. For example, offering a complex machine tool as a

Product Service System (PSS) provides multiple benefits to both the manufacturer of the machine tool as well as the user. The manufacturer has access the usage data as input for next generation designs, a continuous revenue stream, and a closer relationship with its customers, while the users

benefit from reduced initial investments, reduced maintenance efforts, and regular upgrades. While these theoretical benefits are very attractive, there are several issues to be figured out regarding these new business models, such as revenue sharing, data ownership, etc.

Concluding remarks

After we have now covered the background of Smart Manufacturing and Industry 4.0, discussed associated technologies and enabling factors, and identified opportunities to advance the field, the final question remains open: Why are IEs uniquely qualified to address the challenges

put forth by the digital transformation of industry? The answer is simply: This brave new world requires interdisciplinary experts that are trained to think in systems, actually systems of systems, and to deal with complexity efficiently and effectively – who is better at that than Industrial and Systems Engineers?

References

[1] Kagermann,H., Helbig, J., Hellinger, A. & Wahlster, W. (2013). Umsetzungsempfehlungen für das

Zukunftsprojekt Industrie 4.0: Deutschlands Zukunft als Produktionsstandort

sichern. Abschlussbericht des Arbeitskreises Industrie 4.0, Forschungsunion; Geschäftsstelle der Plattform Industrie 4.0, Berlin, Frankfurt/Main.

[2] Thoben, K.-D., Wiesner, S. & Wuest, T. (2017). “Industrie 4.0” and Smart Manufacturing – A Review of Research Issues and Application Examples. International Journal of Automation

Technology, 11(1), 4-19. DOI 10.20965/ijat.2017.p0004(open access:

link )

[3] Wallace, E. & Riddick, F. (2013). Panel on Enabling Smart

Manufacturing, APMS 2013, State College, USA.

[4] Kusiak, A. (2017). Smart manufacturing must embrace big data. Nature News, 544(7648), 23.

[5] Tao, F., Qi, Q., Liu, A., & Kusiak, A. (2018). Data-driven smart manufacturing. Journal

of Manufacturing Systems.

[6 ] Mittal, S., Kahn, M., Romero, D. & Wuest, T. (2017). Smart Manufacturing: Characteristics, Technologies and Enabling Factors. Part B: Journal of Engineering

Manufacture, Online first, 1-20. DOI 10.1177/0954405417736547 (open access:

link )

[7] Romero, D., Stahre, J., Wuest, T., Noran, O., Bernus, P., Fast-Berglund, A. & Gosecky, D. (2016). Towards

an Operator 4.0 Typology: A

Human-Centric Perspective on the Fourth Industrial Revolution Technologies. International Conference on Computers and Industrial Engineering. 2016, October 29.-31., Tianjin, China. ISSN 2164-8670 cd-rom, ISSN 2164-8689 online

[8] Mittal, S., Khan, M., Romero, D. & Wuest, T. (2018). A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-sized Enterprises (SMEs). Journal

of Manufacturing Systems, 49(2018), 194-214. DOI 10.1016/j.jmsy.2018.10.005

[9] Vijayaraghavan, A., Sobel, W., Fox, A., Dornfeld, D., & Warndorf, P. (2008). Improving Machine Tool Interoperability Using Standardized Interface Protocols: MT Connect. UC Berkeley: Laboratory for Manufacturing and Sustainability